The world of fashion is often seen through the lens of runway shows and glossy magazine spreads, but there's a less glamorous yet crucial part of the industry that deserves attention: the production process of handbags and purses. This intricate journey from concept to creation is where the true craftsmanship lies. It's a process that requires ample time, meticulous attention, and careful management to ensure that each handbag is a masterpiece of design and function.

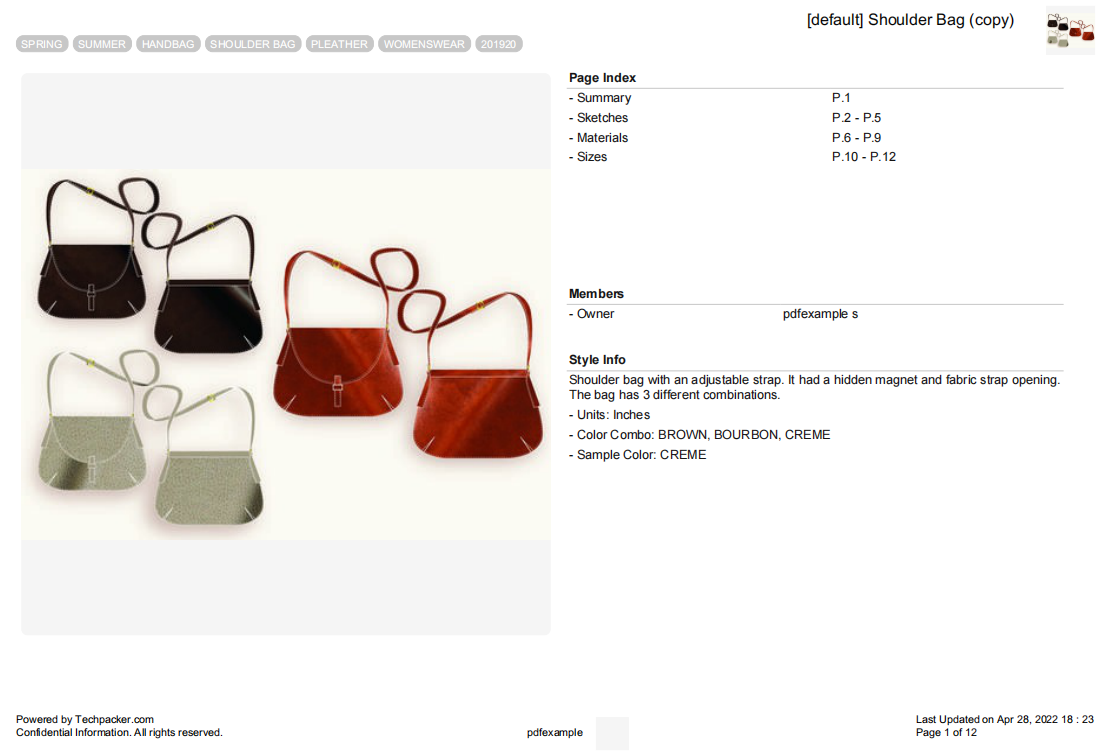

Designing and Preparing Tech Packs

The foundation of any handbag begins with the design, which is meticulously detailed in a Tech Pack. This document is the blueprint for production, ensuring that every stitch, seam, and material is accurately represented. A well-prepared Tech Pack is essential to minimize errors and reduce the number of revisions needed, streamlining the process from the designer's vision to the manufacturer's hands.

Sample Development

Before full-scale production can commence, sample development is a critical step. This phase involves:

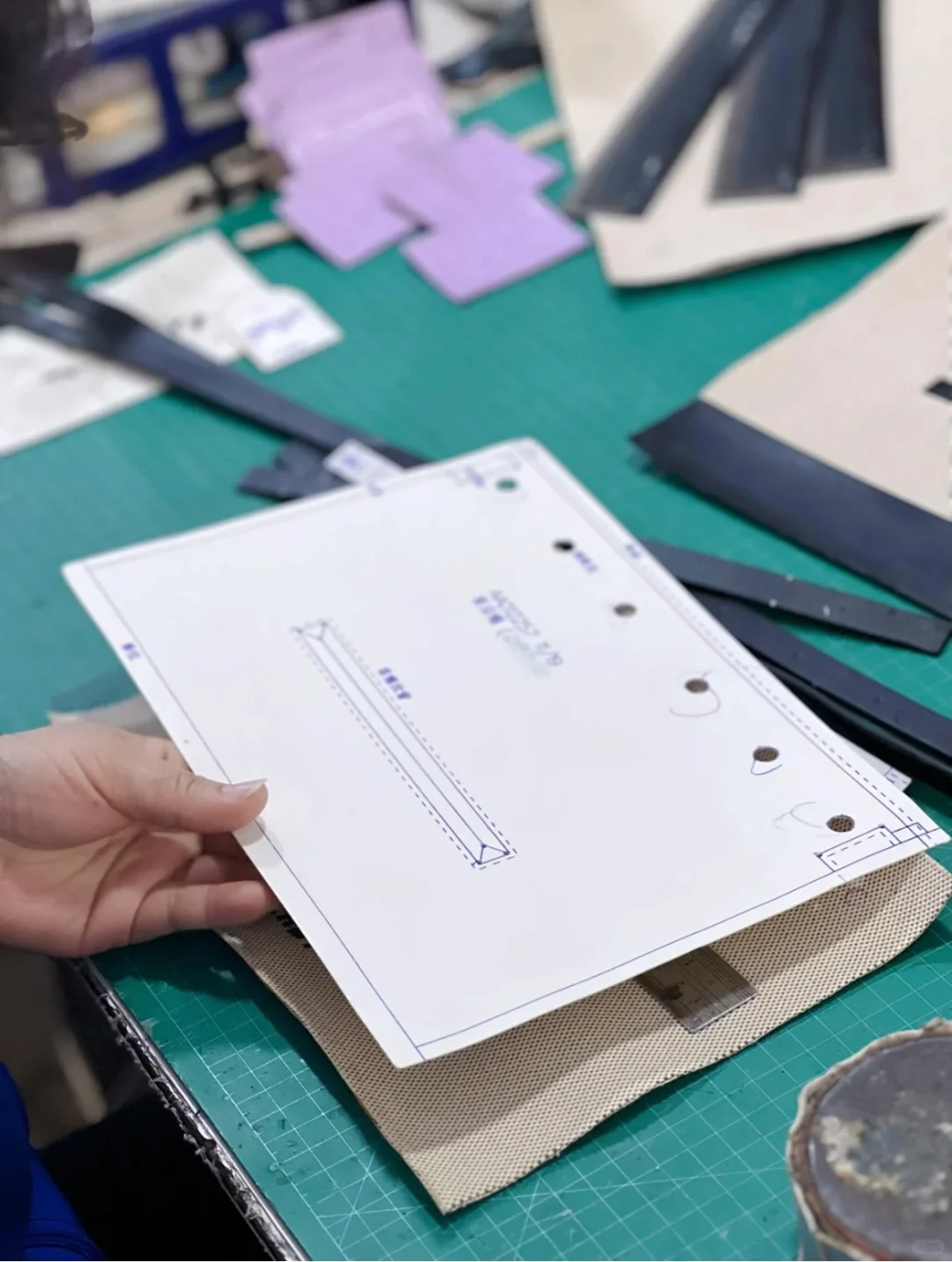

Pattern Making

Creating the paper pattern that will guide the cutting and assembly of the handbag.

Material Sourcing

Securing the fabrics, leathers, and hardware that will bring the design to life.

Prototyping

The actual construction of the sample bag, allowing for a tangible evaluation of design elements and functionality.

Mass Production

Once the sample has been approved, the journey into mass production begins. This phase is broken down into several key steps:

Bulk Material Procurement and Quality Inspection

Sourcing the materials needed for production in large quantities, followed by a thorough quality check to ensure consistency and meet the design specifications.

Material Preparation and Cutting

This involves cutting the materials to size, applying adhesives where necessary, and preparing the edges for a clean finish with processes like oiling and adding some hardware.

Mid-Production Quality Check

A critical stage to identify and rectify any issues before they become more costly to fix later in the process.

Sewing and Assembly

This is where the handbag comes together, with a series of detailed steps including:

- Sewing lining

- Sewing on labels and tags

- Adding structural elements like boning

- Attaching front pockets and flaps

- Sewing velcro

- Finishing edges with binding

- Attaching cover pieces

- Sewing side pockets and back straps

- Installing zippers and buttons

Final Quality Inspection

The last checkpoint to ensure that each handbag meets the highest quality standards before packaging.

Packaging and Shipping

The final stage, where handbags are carefully packaged to protect them during transit and then shipped to retailers or directly to consumers.

Conclusion

The production process of handbags and purses is a testament to the dedication and skill of those in the fashion industry. From the initial design to the final product, each step is a careful balance of artistry and precision. Understanding this process not only sheds light on the hard work behind the scenes but also adds a deeper appreciation for the handbags and purses we carry every day.